VERSATILE.SCALABLE.SIMPLE

| Motion | Horizontal, Vertical |

| Max Speed - Horizontal[Vertical] - mm/sec | 2000[2000] |

| Max Force - Horizontal[Vertical] - lbf | 500[500] |

| Repeatability - mm | +/- 0.025 |

| Moment Load - in-lbs[Nm] | N/A |

| Positional Accuracy - mm/meter | +/- 0.4 |

| Acceleration Max - Gs | 5 |

| Recommended Belt Running Load - lbf[N] | 500 |

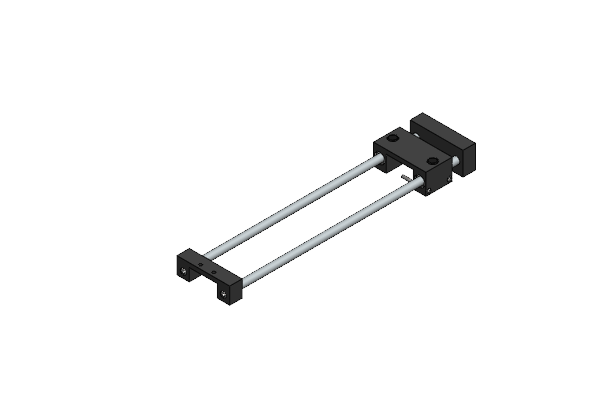

| Cart Guide | Linear bearing with profile rail |

| System Weight - kg | (Travel in meters x 12.2) + 19.4 |

| Weight of Cart - lbs[kgs] | see data sheet |

| Weight of Belt - kgs based on travel selected | ((Travel in meters x 2)+ .74) x . 34 |

| Travel per Revolution - mm | 150 |

| Pulley Pitch Diameter - mm | 47.75 |

| Pulley Material / Width - mm | steel / 54 |

| Breakaway Torque - oz-in | 30 to 32 |

| Coefficient of Friction | 0.1 |

| Standard Travels - min to max | 150 to 5725 |

Enter your configuration options to submit a Request for a Quote or a CAD drawing:

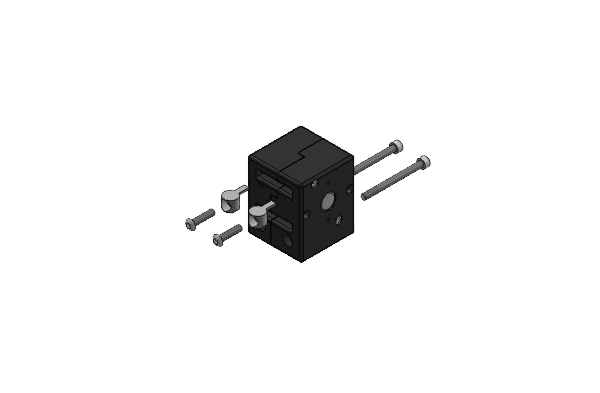

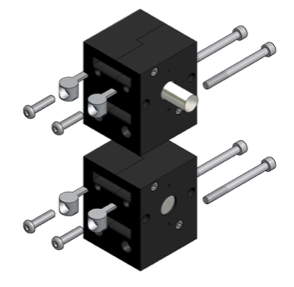

Fits Actuator: MSA-BT5

Fits Actuator: MSA-BT5

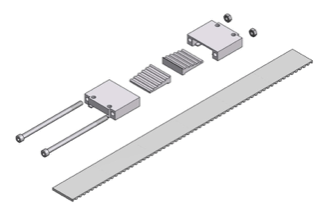

Fits actuators: MSA-SB5, MSA-BT5

Fits actuators: MSA-SB5, MSA-BT5