Job Stories

A client in the transportation industry added a customized Macron solution to their manufacturing process improving efficiency, decreasing costs and shortening production time.

Industry: Transportation sector, product manufacturing

Problem: A client in the transportation industry who manufactures semi-trailers needed to improve the production process for drilling and riveting the various components during trailer construction. Since assembling the composite panels required drilling many holes for the downstream riveting process, automating this process was highly desirable. Typically, conventional CNC drilling heads cannot cover the hole pattern array or meet the process cycle time goals – adding cost and increasing production time.

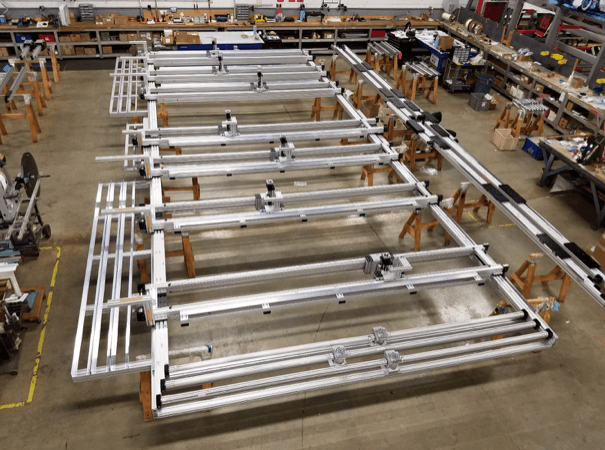

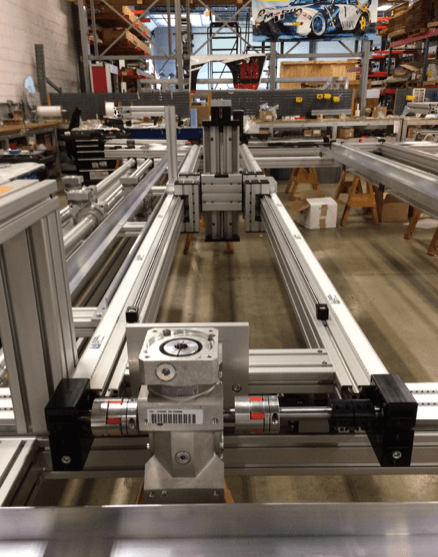

Solution: Macron Engineers developed a large footprint 21 axis gantry system, approximately 4 meters wide by 10 meters long. This system included seven MGS-UC2 MacSTANDARD linear gantries with MSA-DRT screw tables to provide mounting for the drilling heads. This allowed for rigid Z axis vertical motion and the absorption of vibration and forces during operation. Macron chose the UC2 design to meet the travel span and desired deflection specifications of the project. Plus, the seven systems were identical, which reduced spare parts inventory requirements and maintenance.

There were several unique design features for this solution, including independent movement of each Y/Z axis and a unique X Axis construction that consisted of two pairs of three nested profile-rail guided belt drives. These belt drives were spliced together by a pair of MSA-R20 actuators to drive the 7th YZ gantry.

System benefits: Each axis has two timed belts and linear rail guides for precise repeatability and parallel tracking. Each drill head can cover a prescribed process zone, but can also overlap its neighbor to optimize the drilling cycle time depending on hole pattern arrangement.

Contact a Macron representative today to learn how we can help solve your motion challenges!

Stay Updated

Want to keep up on Macron Dynamics technical data and updates? Subscribe below.

Multi-Axis

Cartesian robots deliver precision, scalability, and cost savings for modern manufacturers. Their customizable design and seamless integration make them ideal...

Multi-Axis

Explore how Macron Dynamics engineered a water resistant, belt drive actuator for a Smart Engineering Solutions company for educational use...

Multi-Axis

In search of an automated solution to increase productivity and decrease safety hazards, OES Automation worked with Macron Dynamics to...

We've got some fantastic news to share — We are not affected by the recent tariffs.

As a proud USA-based company where all our Engineering, Manufacturing and Application Support is located in Croydon, PA.

We're thrilled to let you know:

Whether you're a longtime customer (thank you for your continued support!) or someone we haven't worked with yet — we'd love to connect and show you what sets us apart.

Let's grow together — tariff-free and stress-free.