Job Stories

A large dairy products packaging company required rapid vertical axis travel in their case packaging and bottling lines automation. Product was being moved over long spans between multi-level conveyor systems. Case packaging operations required a fast pace and long Z axis stroke to move product.

Application: Automated case packaging

Industry: Wine packaging / dairy products

Problem:

A large dairy products packaging company required rapid vertical axis travel in their case packaging and bottling lines automation. Product was being moved over long spans between multi-level conveyor systems. Case packaging operations required a fast pace and long Z axis stroke to move product. End effectors are often large and heavy which can introduce a pendulum effect.

Solution:

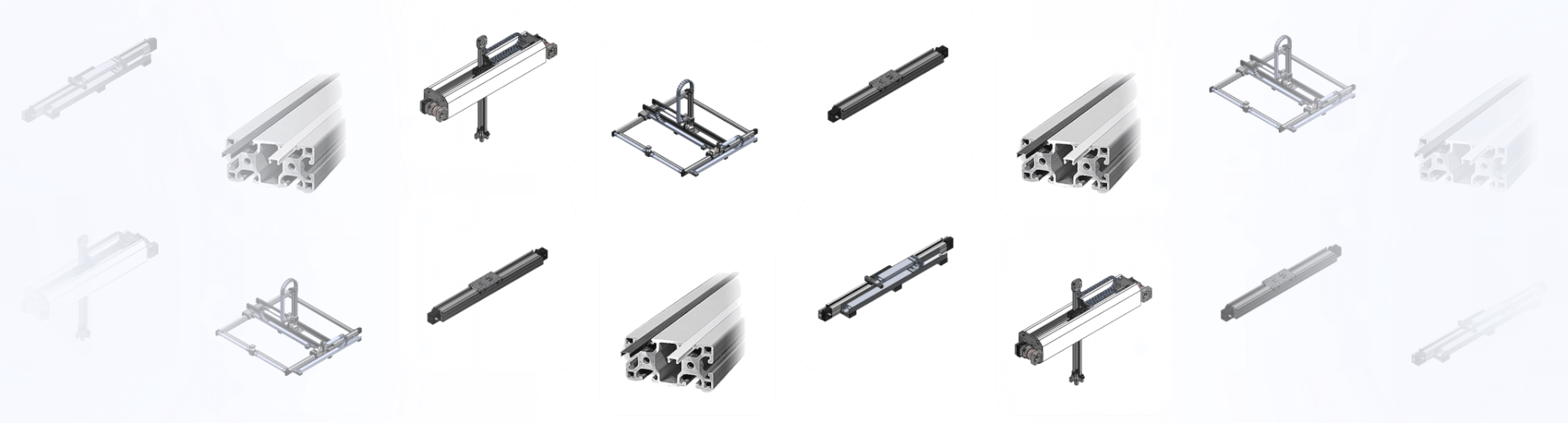

Macron application engineers suggested using a MacBUILT Dual X / Dual Z configuration consisting of MSA-14 heavy duty actuators.To counter the buildup of inertial forces, Macron’s dual configuration design provides stability without sacrificing speed. Dual belts help safeguard productivity by assuring that if one belt fails, the second will continue working until replacement.

MacBUILT Gantry Systems Feature:

System benefits:

As added protection against load carriage free-fall, Macron can now install the patent pending CLAWS vertical arresting system to protect product and machinery in the event of belt breakage.

Heavy-duty Macron MSA-14H belt drives feature rigid construction to meet requirements for robust operation typical in automated case packaging machinery. The Macron units handle long travel requirements for up to 1869 mm. The MSA-14H can move vertical payloads of 300 pounds at rates of 5080 mm/second with +/- 0.025 mm repeatability.

Macron has over 25 years of experience in meeting innovative and demanding challenges for belt driven actuators in packaging systems, pick-and-place equipment, and a wide range of other production machinery.

Customer comments:

“Macron does it right. Their Cartesian gantry system is far more economical than a multi-axis robot for pick and place activities. In addition Macron can lengthen any axis to fit our application requirements creating a standardized platform that can be replicated for any project, saving re-engineering costs.” — West Coast System Integrator —

Stay Updated

Want to keep up on Macron Dynamics technical data and updates? Subscribe below.

Multi-Axis

Cartesian robots deliver precision, scalability, and cost savings for modern manufacturers. Their customizable design and seamless integration make them ideal...

Multi-Axis

Explore how Macron Dynamics engineered a water resistant, belt drive actuator for a Smart Engineering Solutions company for educational use...

Multi-Axis

In search of an automated solution to increase productivity and decrease safety hazards, OES Automation worked with Macron Dynamics to...

Macron Dynamics specializes in designing and building virtually any configuration to meet your unique automation needs. Our innovative solutions enhance efficiency, optimize workspace utilization, and prioritize worker safety—reducing injuries while maximizing productivity.

We offer custom solutions for applications requiring from one to thousands of units. And units physically much smaller and larger than our standard models.