Job Stories

See how a MacBUILT XYZ Gantry is an integrated part of this commercial outdoor products manufacturer's complex fabrication process.

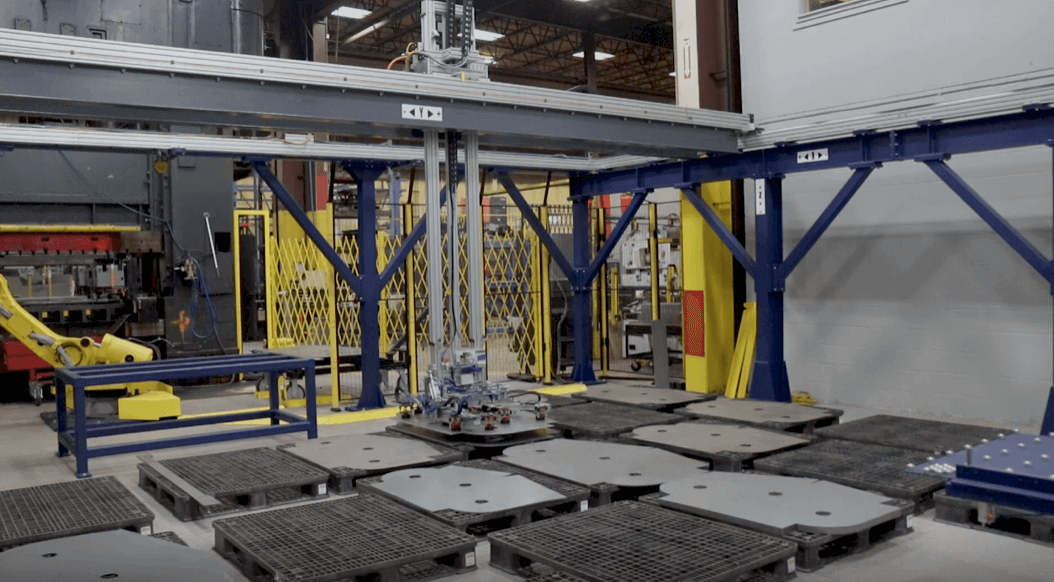

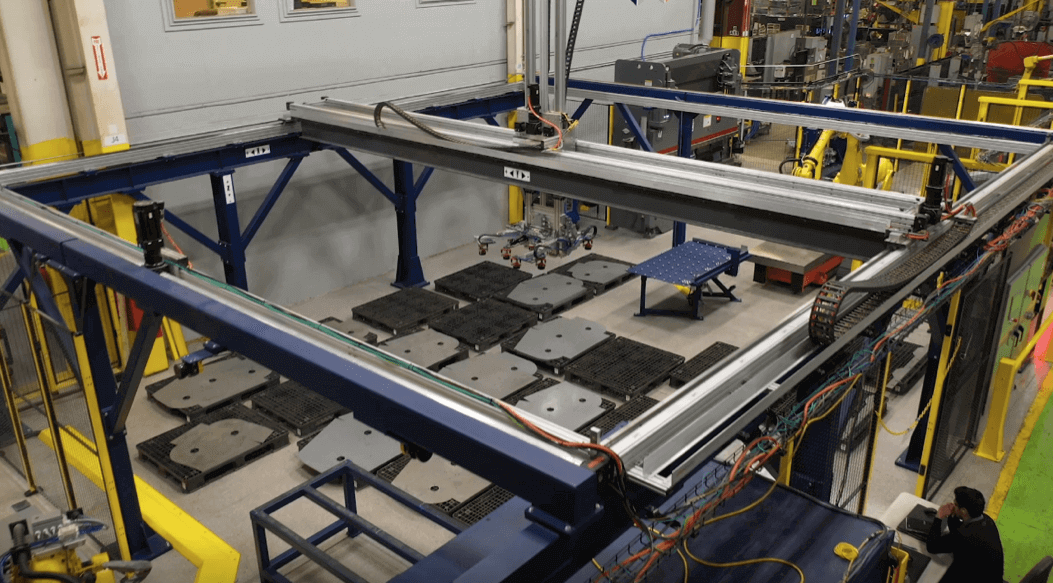

Application: MacBUILT 3 axis X,Y & Z Cartesian Gantry system

Industry: Commercial Outdoor Equipment Product Manufacturing

Problem: A client recently came to Macron Dynamics seeking a highly flexible work cell to press stamp product blanks into shape and stack the various products within a WIP area. The work cell was initiated by a signal which triggered an ordered sequence that moved the product blanks into a forming station. A six-axis robot handled the product moving it from flat sheet to stamped blank upstream of the Macron Cartesian Gantry System. A different six-axis articulated arm robot then moved the blank through a forming station downstream. The large gantry system moving on X, Y, and Z axes and equipped with a complex heavy-duty end effector facilitates the product movement between the work cells manned by the articulated arm robots using coordinated cartesian motions.

Solution: What started as an inquiry about Macron’s specialty capabilities quickly transformed into a sophisticated solution for a flexible work cell. Macron Engineers worked through the application requirements with the client’s System Integration Engineers to develop a comprehensive solution that was capable of meeting the unique challenges that this scenario presented – including a very long span between work cells. Based on this plan, it was determined that a MacBUILT MCS Heavy Duty Cartesian Gantry System would be ideally suited to perform the job.

MacBUILT systems are hybrid combinations of our MacSTANDARD actuators and gantry systems. In this application, an MGS-UC3 Heavy Duty X/Z gantry was set on an MDS-14H Heavy Duty Dual extended cart system to deliver 3 axes of motion and a large footprint with extra-long reach capabilities vertically. Since the Y-axis travel exceeded the standard MGS-UC3 limits, a pair of special composite “I” beams were attached to the Y-axis beams to provide extra strength and reduced deflection over the long travel distances without adding significant weight to the moving mass load. As demonstrated in the video, the system is running efficiently and essentially “lights out” with no operators.

When asked why this client sought out Macron Dynamics to solve their unique challenges the answer was simple. According to Craig Marshall, Chief Operating Officer, “We are the best linear robotic solution for this particular problem. When it comes to customizing sophisticated cartesian gantry systems – especially those that need to cover a large work envelope – Macron Engineers are the experts.”

Do you need a unique custom solution for your next automation system project? Explore Macron Dynamics’ linear robots as an option. We specialize in developing and delivering solutions that meet your project needs. Contact a Macron representative to share your project requirements and connect with our creative Application Engineers. We look forward to supporting your single or multi-axis project!

Stay Updated

Want to keep up on Macron Dynamics technical data and updates? Subscribe below.

Multi-Axis

Cartesian robots deliver precision, scalability, and cost savings for modern manufacturers. Their customizable design and seamless integration make them ideal...

Multi-Axis

Explore how Macron Dynamics engineered a water resistant, belt drive actuator for a Smart Engineering Solutions company for educational use...

Multi-Axis

In search of an automated solution to increase productivity and decrease safety hazards, OES Automation worked with Macron Dynamics to...

Macron Dynamics specializes in designing and building virtually any configuration to meet your unique automation needs. Our innovative solutions enhance efficiency, optimize workspace utilization, and prioritize worker safety—reducing injuries while maximizing productivity.

We offer custom solutions for applications requiring from one to thousands of units. And units physically much smaller and larger than our standard models.