VERSATILE. SCALABLE. SIMPLE.

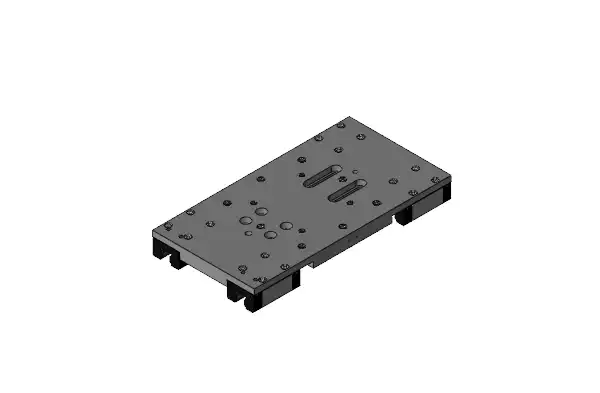

The MRA-RTU-1 Robot Transfer Unit is a 7th-axis linear actuator designed for precise motion in industrial automation and robotic applications. It features an aluminum cart matched to the robot model and an extruded aluminum actuator body with T-slots for flexible mounting. The MRA-RTU-1 supports user-defined stroke lengths, smooth high-speed travel, and near-zero backlash for accurate, stable positioning. Built with corrosion-resistant components, it provides long-lasting durability and minimal maintenance in demanding environments.

Each RTU can be supplied with T-slot sensors, gearboxes, or motor mounting adaptors upon request. For travel requirements over standard values, contact Macron Dynamics for assistance.

These are standard specifications, if you need a custom configuration, please use our custom configuration request form.

| Motion | Horizontal, Vertical |

| Max Speed - Horizontal[Vertical] - mm/sec | 3000[3000] |

| Max Load - Horizontal[Vertical] - lbs | 1000[500] |

| Repeatability - mm | +/- 0.025 |

| Moment Load - in-lbs[Nm] | 4400[497] |

| Positional Accuracy - mm/meter | +/- 0.4 |

| Acceleration Max - Gs | 1 |

| Recommended Belt Running Load - lbf[N] | 437[1945] |

| Cart Guide | Linear bearing with profile rail |

| System Weight - kg | See Data Sheet |

| Weight of Cart - lbs[kgs] | See Data Sheet |

| Weight of Belt - kgs based on travel selected | See Data Sheet |

| Travel per Revolution - mm | See Data Sheet |

| Pulley Pitch Diameter - mm | See Data Sheet |

| Pulley Material / Width - mm | See Data Sheet |

| Breakaway Torque - oz-in | 30 to 32 |

| Coefficient of Friction | 0.1 |

| Standard Travels - min to max | 150 to 5725 |

Enter your configuration options to submit a Request for a Quote or a CAD drawing:

Fits actuators: MSA-R2D, MRA-RTU-1 and MRA-RTU-1i

Includes complete cart assembly with mounting hardware. Special adjustment tools if required, sold separately

Download Datasheet

Macron Dynamics specializes in designing and building virtually any configuration to meet your unique automation needs. Our innovative solutions enhance efficiency, optimize workspace utilization, and prioritize worker safety—reducing injuries while maximizing productivity.

We offer custom solutions for applications requiring from one to thousands of units, and units physically much smaller and larger than our standard models.