Job Stories

Macron recently delivered a custom solution for OEM special machinery manufacturer who required washdown-capable actuators for a stack feeder inside their newest meat packaging system.

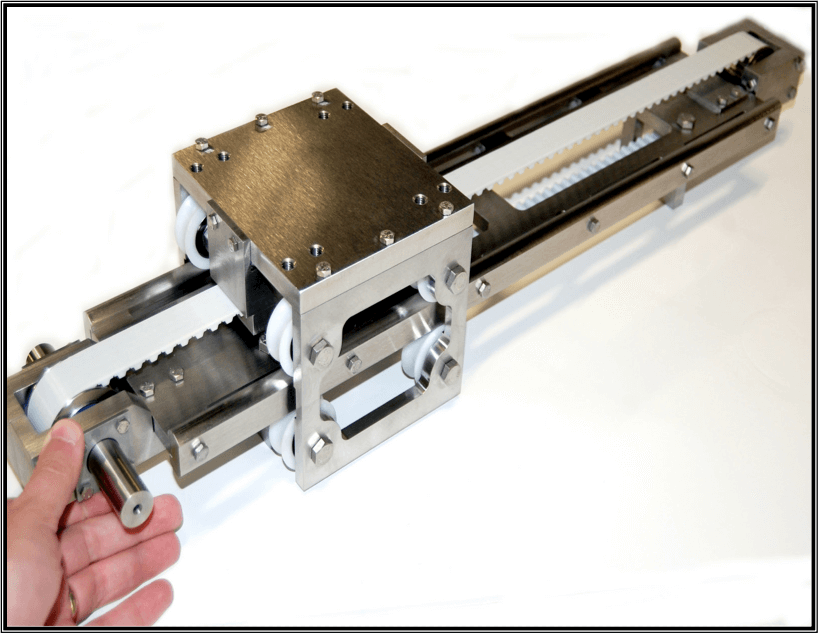

Application: Washdown Actuator

Industry: Food Packaging

Problem:

An OEM special machinery manufacturer required custom actuators for a stack feeder inside their newest meat packaging system. The system required rigorous washdown processes for sanitary purposes while maintaining similar speed and weight capabilities as the all aluminum and steel Macron 14 roller cart actuator.

Solution:

To provide the manufacturer with a corrosion resistant actuator capable of sanitary washdown rigors, Macron Dynamics designed a custom actuator fabricated almost entirely from stainless steel, including all carts, beams, and hardware. Food grade polymers and stainless steel replaced steel rollers and bearings. The pulley housings were redesigned as open elements with generous clearances to allow easy cleaning and inspection.

System benefits:

Primarily as a result of its stainless steel components, the actuator is impervious to corrosion and judged suitable by the customer for food grade material handling usage. In addition to resisting rust tarnish and corrosion in such a severe environment, the actuator was deployed carrying loads of up to 18 lbs. at a speed of 1 foot per second. Due to its open design, the actuator is easily accessible for cleaning and inspection.

A line of stainless steel Macron Dynamics MacBUILT products is expected to be released in 2013.

Click here to see the system in action!

Multi-Axis

Explore how Macron Dynamics engineered a water resistant, belt drive actuator for a Smart Engineering Solutions company for educational use...

Multi-Axis

In search of an automated solution to increase productivity and decrease safety hazards, OES Automation worked with Macron Dynamics to...

Multi-Axis

Explore how Macron Dynamics used an X/Z Heavy Duty Gantry System for a beverage industry customer’s pick and place packaging...