Job Stories

A product test station required an overhead transport system with integrated frame. Due to testing parameters the entire system needed to be non-reflective. Standard clear anodized aluminum components would not meet the requirement.

Industry: Solar Energy Panel Manufacturing

Challenge:

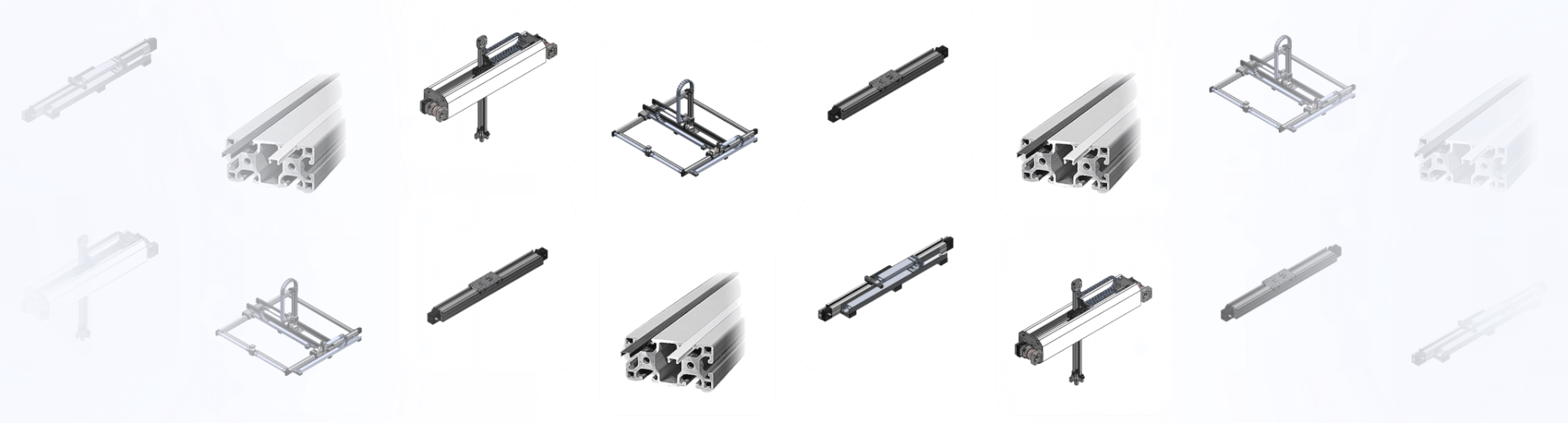

A product test station required an overhead transport system with an integrated frame. Due to testing parameters the entire system needed to be non-reflective. Standard clear anodized aluminum components would not meet the requirement.

Solution: Macron 6 Cartesian Robot Gantry System

Stay Updated

Want to keep up on Macron Dynamics technical data and updates? Subscribe below.

Multi-Axis

Cartesian robots deliver precision, scalability, and cost savings for modern manufacturers. Their customizable design and seamless integration make them ideal...

Multi-Axis

Explore how Macron Dynamics engineered a water resistant, belt drive actuator for a Smart Engineering Solutions company for educational use...

Multi-Axis

In search of an automated solution to increase productivity and decrease safety hazards, OES Automation worked with Macron Dynamics to...

Macron Dynamics specializes in designing and building virtually any configuration to meet your unique automation needs. Our innovative solutions enhance efficiency, optimize workspace utilization, and prioritize worker safety—reducing injuries while maximizing productivity.

We offer custom solutions for applications requiring from one to thousands of units, and units physically much smaller and larger than our standard models.