Job Stories

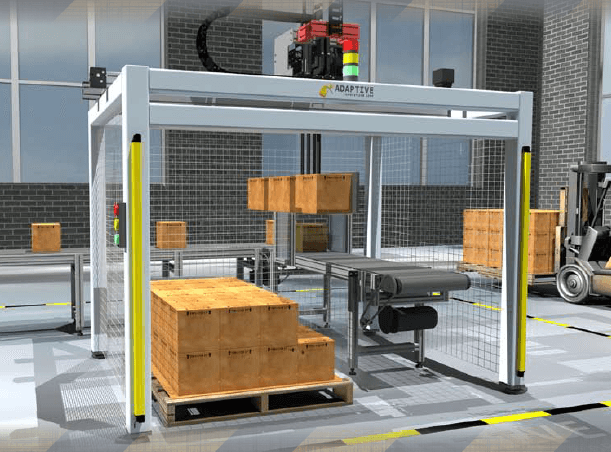

Recently, a Macron Dynamics system integrator, Adaptive Innovations Corp. of Lakewood Colorado, developed a 2-axis, high speed X/Z Row Palletizing / De-palletizing system. To provide X/Z motion, the company integrated a Macron MGS-UC2 linear robot kit.

Industry: Packaging & Palletizing

Putting products in cartons and placing cartons, buckets, cans or totes on pallets is a manually intense process ripe for automation. Investing in linear robots for material handling provides quick payback and allows for re-deploying manpower to more effective tasks.

Recently, a Macron Dynamics system integrator, Adaptive Innovations Corp. of Lakewood Colorado, developed a 2-axis, high speed X/Z Row Palletizing / De-palletizing system. To provide X/Z motion, the company integrated a Macron MGS-UC2 linear robot kit.

The palletizer’s design is economical and one of the smallest footprints in the industry. With a payload capacity of 150 pounds and up to 90 cases per minute cycle, the system is flexible enough to carry a wide variety of products.

This automated palletizing system demonstrates you don’t need an articulated arm robot for this type of process, as commonly thought. In fact, a linear robot with Cartesian positioning is more than adequate for the task – providing a longer Z-axis reach for those tight pallet stacking or un-stacking requirements.

With the help of Macron’s X/Z palletizing gantry kit, the automated palletizing machine:

System benefits:

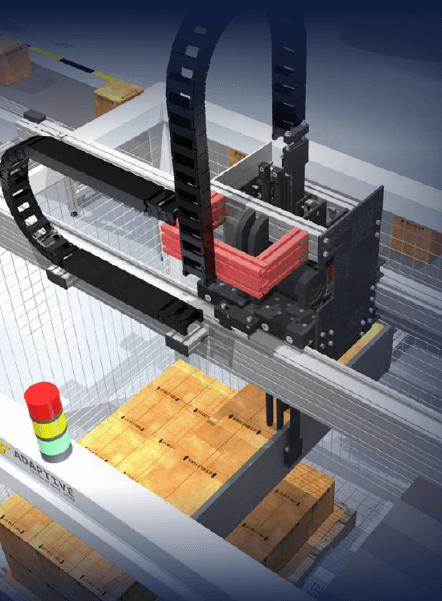

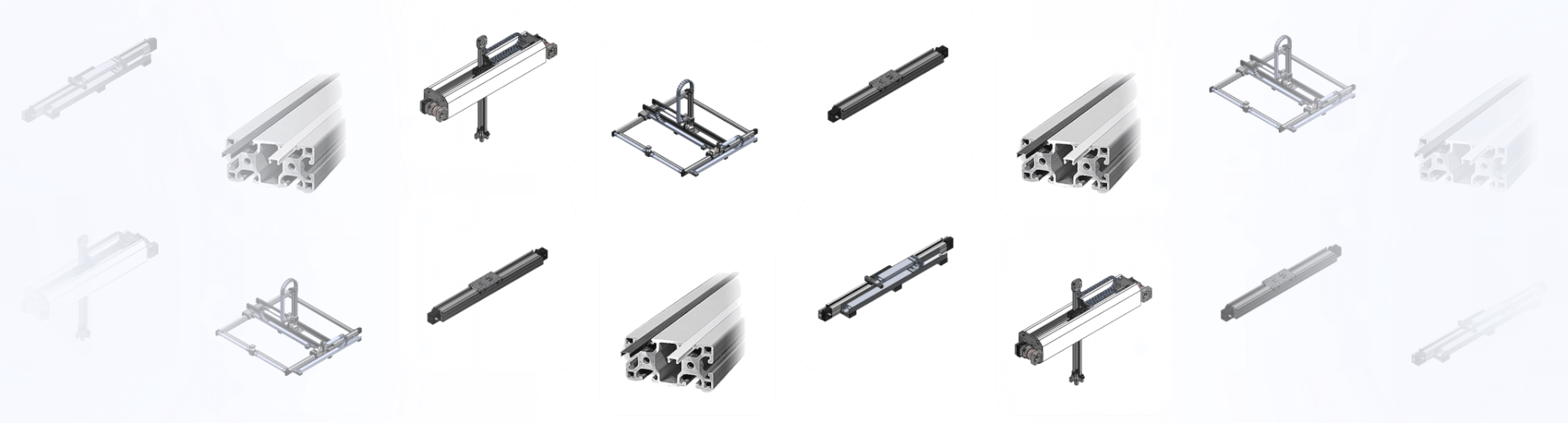

The Macron MGS-UC2 gantry product is a robust and durable 2-axis system with broad payload capacity. Belt driven in each axis, the unit is fast and repeatable. This ready-made kit, in pre-configured standard travel lengths, includes integrated cable management, low profile T-slot sensors and MPG gearboxes ready for any motor mounting.

Customer comments:

Macron’s palletizing gantry kit provided a hassle-free, practically out-of-the-box solution. It’s modular design allowed us to easily integrate it into our palletizing process and overall system including grippers and conveyors.

Is this solution a fit for your automation needs?

Contact your Macron representative or Macron direct for more information on our Linear Robot kits for packaging applications.

Stay Updated

Want to keep up on Macron Dynamics technical data and updates? Subscribe below.

Multi-Axis

Cartesian robots deliver precision, scalability, and cost savings for modern manufacturers. Their customizable design and seamless integration make them ideal...

Multi-Axis

Explore how Macron Dynamics engineered a water resistant, belt drive actuator for a Smart Engineering Solutions company for educational use...

Multi-Axis

In search of an automated solution to increase productivity and decrease safety hazards, OES Automation worked with Macron Dynamics to...

Macron Dynamics specializes in designing and building virtually any configuration to meet your unique automation needs. Our innovative solutions enhance efficiency, optimize workspace utilization, and prioritize worker safety—reducing injuries while maximizing productivity.

We offer custom solutions for applications requiring from one to thousands of units, and units physically much smaller and larger than our standard models.