Job Stories

Cartesian robots deliver precision, scalability, and cost savings for modern manufacturers. Their customizable design and seamless integration make them ideal for assembly, packaging, and material handling. A proven automation solution, they maximize efficiency while reducing costs

Manufacturers today face constant pressure to improve efficiency, reduce costs, and deliver consistent quality. To achieve this, many companies are turning to Cartesian robots—also known as Cartesian gantry robots or linear robotic systems—as a proven automation solution. With their straightforward design and unmatched flexibility, these robots are becoming an essential tool for industries ranging from aerospace and automotive to packaging, medical, and electronics.

Performance and Reliability

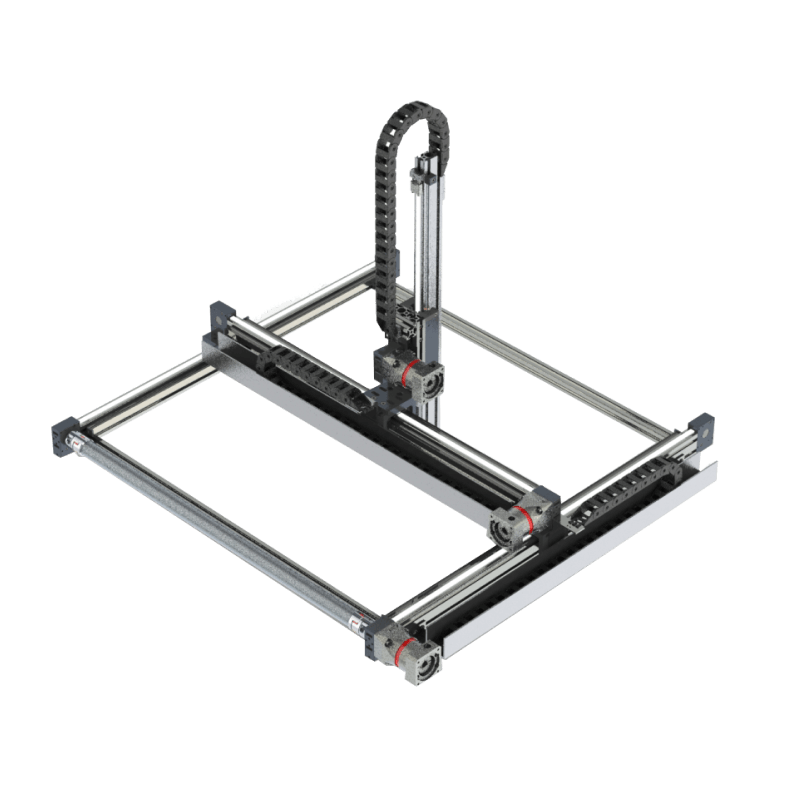

One of the most significant advantages of Cartesian robots is their range of motion in 3 axes. Their linear motion along the X, Y, and Z axes makes them inherently accurate and highly repeatable, which is vital for operations like pick-and-place, assembly, and inspection. Because of their rigid structural design, Cartesian systems also deliver the strength needed for heavy payloads, excelling in tasks such as palletizing and material transfer where more miniature articulated robots often struggle. This balance of accuracy and durability allows them to handle both delicate and demanding industrial loads.

Scalable, Custom, and Cost-Effective

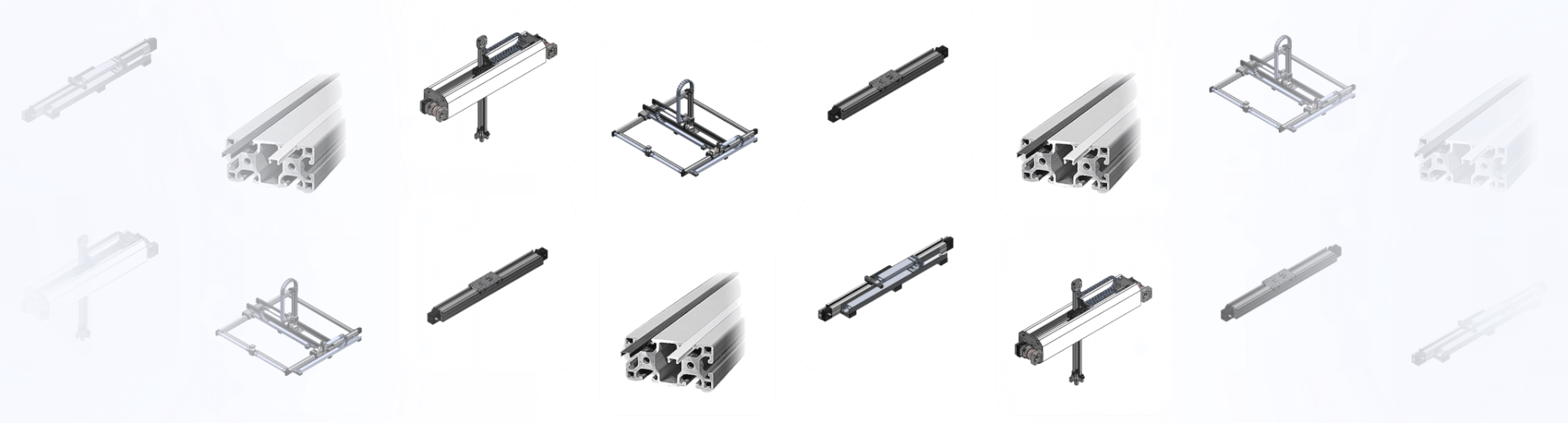

Unlike robotic arms that come in fixed sizes and reach, Cartesian robots can be scaled and configured to fit almost any workspace. A system might be as simple as a single-axis actuator or as large as a multi-axis gantry spanning an entire factory floor. With modular designs like those engineered by Macron Dynamics, these systems can be tailored to the travel lengths, load capacity, and speed requirements of each application. At the same time, their straightforward mechanical design often makes them more affordable than SCARA or articulated robots—both in terms of upfront investment and long-term maintenance. For manufacturers seeking automation without excessive cost, Cartesian robots provide an efficient path forward.

Seamless Integration and Workspace Efficiency

Beyond performance and cost, Cartesian robots stand out for their ease of integration into production environments. Their modular gantry systems connect seamlessly with conveyors, sensors, tooling, and machine centers, allowing manufacturers to automate without rethinking entire processes. Because these systems can be designed with long travel distances, they maximize workspace coverage, making them ideal for large surfaces, extended assembly lines, or multi-station operations. This flexibility ensures companies get the most out of their floor space while maintaining efficiency.

Why Choose Macron Dynamics?

Macron Dynamics has decades of experience designing and manufacturing American-made Cartesian robots that combine durability with adaptability. Our modular systems are built for industrial environments that demand strength and reliable performance, while still offering the flexibility to grow and change as automation needs evolve. With proven engineering expertise and a focus on performance, Macron helps manufacturers improve productivity, lower costs, and stay competitive in today’s fast-moving markets.

Cartesian robots offer a potent mix of scalability, accuracy, and efficiency. That’s why an increasing number of companies are relying on them as the foundation of their automation strategy. Learn more about Macron’s Cartesian Robots or contact us to explore a system designed for your application.

Stay Updated

Want to keep up on Macron Dynamics technical data and updates? Subscribe below.

Multi-Axis

Cartesian robots deliver precision, scalability, and cost savings for modern manufacturers. Their customizable design and seamless integration make them ideal...

Multi-Axis

Explore how Macron Dynamics engineered a water resistant, belt drive actuator for a Smart Engineering Solutions company for educational use...

Multi-Axis

In search of an automated solution to increase productivity and decrease safety hazards, OES Automation worked with Macron Dynamics to...

Macron Dynamics specializes in designing and building virtually any configuration to meet your unique automation needs. Our innovative solutions enhance efficiency, optimize workspace utilization, and prioritize worker safety—reducing injuries while maximizing productivity.

We offer custom solutions for applications requiring from one to thousands of units. And units physically much smaller and larger than our standard models.