Job Stories

A client in the thermal processing market required an automated XZ gantry system capable of steadily dipping products into heavy crucible of hot salts during thermal procedures.

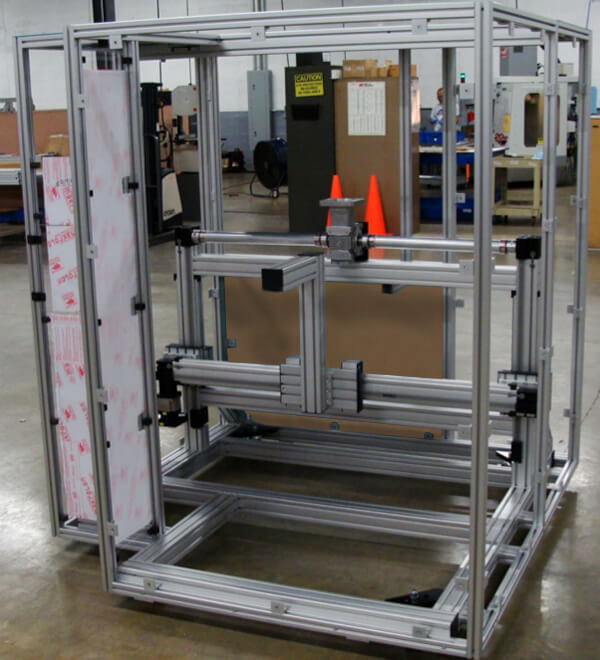

Application: Thermal Processing XZ Gantry System

Industry: Thermal Processing

Problem: A client in the thermal processing market required an automated XZ gantry system capable of steadily dipping products into heavy crucible of hot salts during thermal procedures.

The linear robot needed to be capable of controlled motions, while avoiding contact with the hazardous materials the machine would be handling through sloshing and spills. The thermal processing client lacked an in-house engineering and manufacturing ability, requiring Macron engineers to develop a custom solution in their manufacturing facility

In addition to controlled motion, the client called for a linear robotic with an enclosed design and mobile functionality to compliment the plant’s floor plan. The system needed to be capable of moving easily and smoothly from one processing station to another.

Solution: Given the client’s lack of in-house engineering, Macron worked collaboratively with the thermal processing company to deliver a linear robotic system constructed with Macron MSA-14S belt driven actuators.

Macron integrated low profile components into the XZ linear robotic system to prevent hazardous materials from making contact with the machine’s parts. To meet the enclosed and mobile design requirements, Macron constructed the linear robot’s outer structure with MacFRAME aluminum extrusions and panels, while mounting the entire framed system on wheels.

System benefits: The system’s lightweight MSA-14S belt driven actuators feature extruded aluminum bodies, allowing for easy mounting. Using belt driven actuators allowed for a longer load travel while requiring less protective shield than its screw driven counterpart. Low profile components lifted and kept systems components out of the processing tank, away from hazardous materials.

The enclosure panels mounted to the MacFRAME aluminum extrusion structure are easily and speedily removed, creating accessibility to parts for maintenance.

Multi-Axis

Explore how Macron Dynamics engineered a water resistant, belt drive actuator for a Smart Engineering Solutions company for educational use...

Multi-Axis

In search of an automated solution to increase productivity and decrease safety hazards, OES Automation worked with Macron Dynamics to...

Multi-Axis

Explore how Macron Dynamics used an X/Z Heavy Duty Gantry System for a beverage industry customer’s pick and place packaging...